Use microfabrication to

give shape to your inspiration.HIKARI LASER LAB.

Realize the “non-thermal/non-contact machining” of all types of material.

Clear challenges of microfabrication and

turn your idea into products.

Features of Hikari Laser Lab

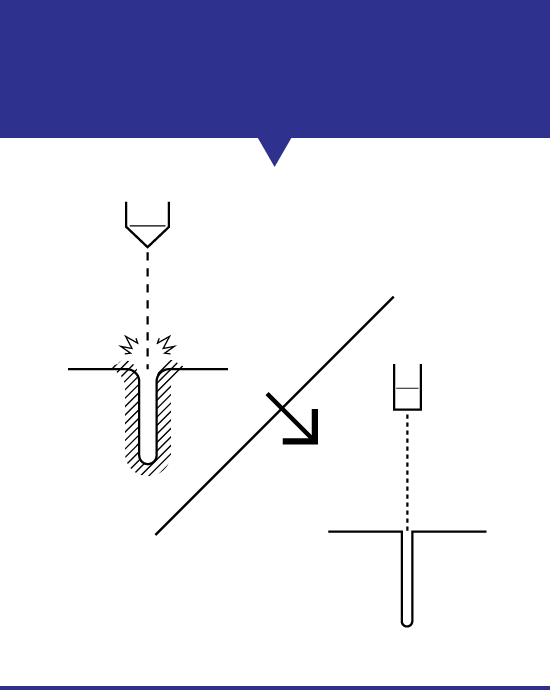

- Realize

damageless machining.

- Realize

prototype idea.

- Realize

OEM products.

- Realize

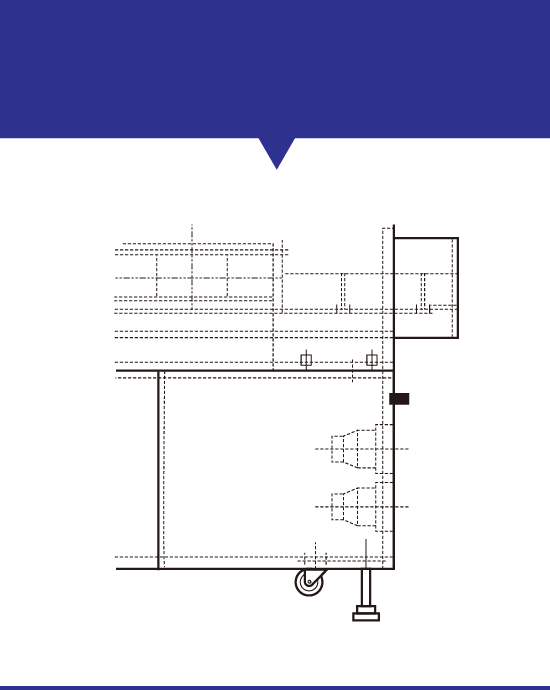

production system.

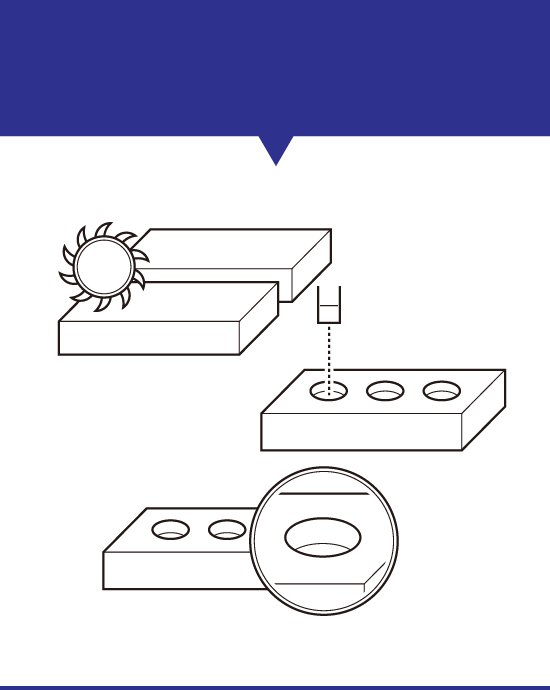

Example of Manufacturing

We conduct microfabrication regardless of material.

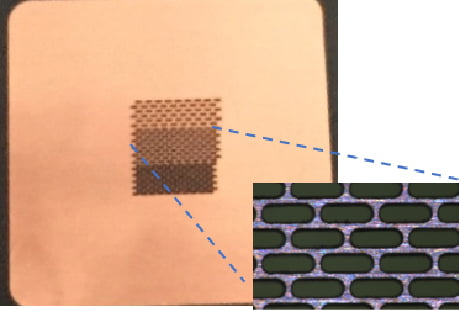

Manufacturing example of copper thin film

- Trimming

- Thickness: 0.1mm

- Retained width in the blowup : 50μm

Scope of Proposal

Parts makers

- Laser oscillator

- Lens/Mirror

- Others

HIKARI LASER LAB.

- Prototype/Development

- Contract machining

- Equipment/System

development - Engineering consulting

Users

- Electronics maker

- Medical/Bio maker

- Auto parts maker

- University/Research

institute

HIKARI LASER LAB.

makes proposals both for

“contract machining" and for “equipment”

- The proposal for optimal machining conditions by engineers/researchers who have long been engaged in laser machining is available.

- The technology and knowhow of a machine maker with more than 70 years of history are used to realize any proposal for the development of equipment.

- The unit price for mass production can be restrained by setting contract machining line consisting of in-house equipment.

- We provide support for prototype, development, small lot OEM to large lot in-house manufacturing.